VIBRATING FEEDERS

Vibrating feeders are designed to transport bulk materials. Construction is based on vibrating troughs excited by properly configurated drives. Vibrating feeders can be applied as output devices, taking material from silos or other containers. Their speed may be adjusted to desired efficiency. Other possible applications are: forming even layers of the product, transport combined cooling or drying process, etc. INWET inc. offers many types of vibrating feeders designed and customized accordingly to customer’s needs.

Every feeder may have support construction designed to fit existing technological line. Feeders are driven by inertial electric vibrators with speed regulation. All elements of such devices, having contact with the product, are easy to clean. Vibrating feeders are also durable and long lasting. When needed, feeders are equipped with chute tanks.

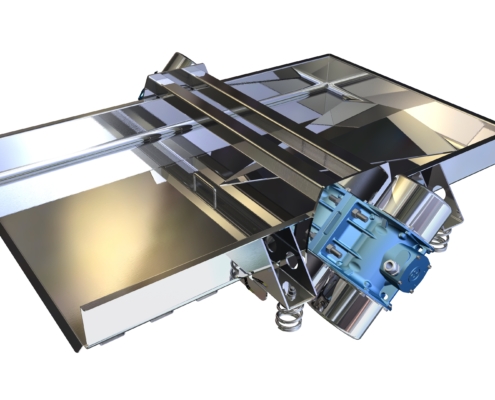

Trough feeders

Vibrating trough feeders are the most popular and convenient kind of feeders used in technological transportation. Accordingly to customer demands, we design troughs of rectangular or trapezoid cross-section shape and with optional lid cover. This equipment is the most suitable for continuous work with a steady efficiency.

Box below shows the basic technical data.

| Maximum dimensions (lenght x width) | 5m x 2m |

| Efficiency | from 1 kg/h to 200 t/h |

| Construction material | Stainless steel AISI 304 Stainless steel AISI 316 Coated carbon steel |

| Drive | Inertial drive |

| Support | Steel bar construction with springs or metal-rubber suspension |

Vibrating feeder

Vibrating screen

Spiral feeder

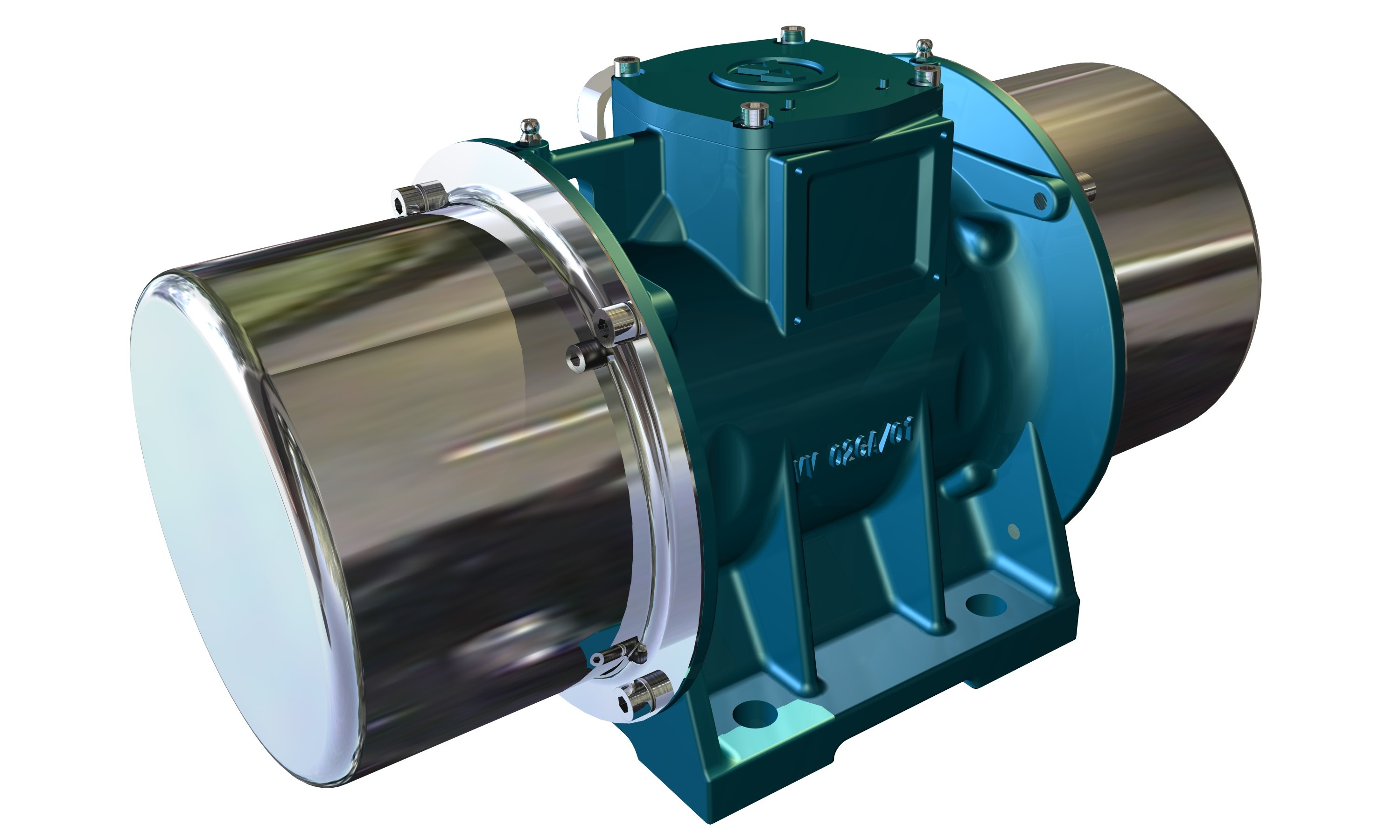

Inertia drive

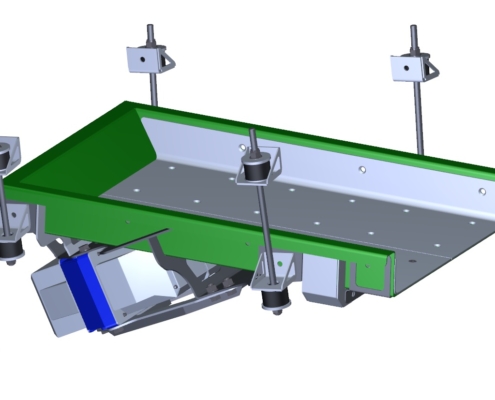

Vibrating feeding screens

Vibrating feeding screens are used for transport of bulk materials with simultaneous fractioning. Usually equipped with changable perforated steel screen or slot screen (dewatering).

Box below shows the basic technical data.

| Maximum dimensions (lenght x width) | 5m x 2m |

| Efficiency | from 1 kg/h to 200 t/h |

| Construction material | Stainless steel AISI 304 Stainless steel AISI 316 Coated carbon steel |

| Drive | Inertial drive |

| Support | Steel bar construction with springs or metal-rubber suspension |

| Screen | Perforated steel sheet or slots |

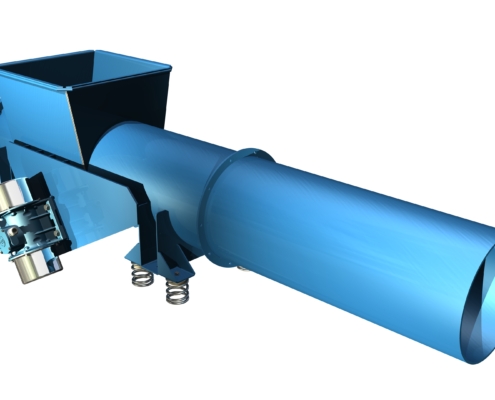

Tubular feeders

Vibrating tubular feeders are designated to transport dusty bulk materials. Diameter depends on expected efficiency, construction material depends on processed product.

Box below shows the basic technical data.

| Maximum dimensions (lenght x diameter) | 5m x Ø0,5m |

| Efficiency | od 1 kg/h do 50 t/h |

| Construction material | Stainless steel AISI 304 Stainless steel AISI 316 Coated carbon steel |

| Drive | Inertial drive |

| Support | Steel bar construction with springs or metal-rubber suspension |

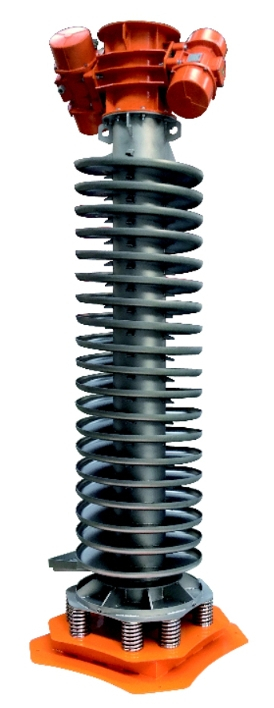

Electromagnetic feeders

Vibrating feeders with electromagnetic drive are designated to perform permanent or gradual flow of bulk materials. Perfect for cooperation with scales.

Box below shows the basic technical data.

| Maximum dimensions (lenght x width) | 5m x 1,5m |

| Efficiency | from 1 kg/h to 200 t/h |

| Construction material | Stainless steel AISI 304 Stainless steel AISI 316 Coated carbon steel |

| Drive | Electromagnetic drive |

| Support | Steel bar construction with springs or metal-rubber suspension |