Air blasters

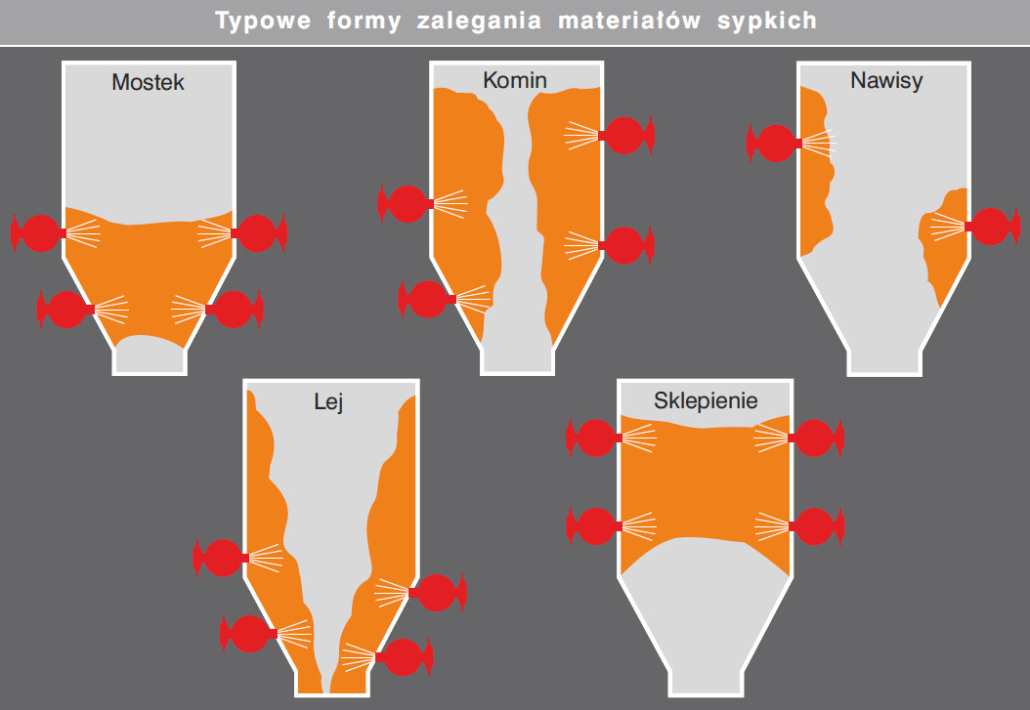

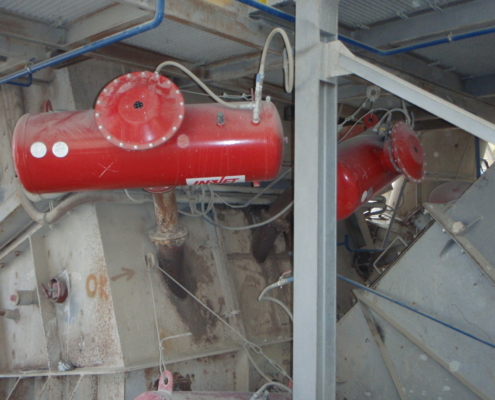

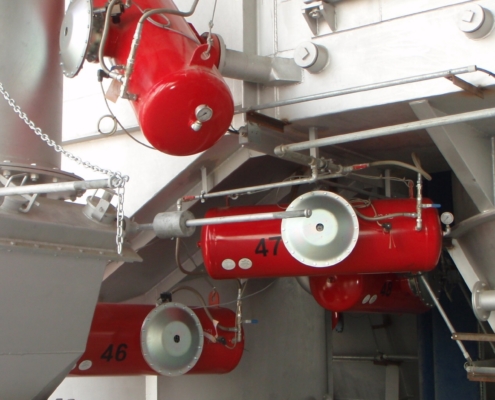

Bulk materials stored in big steel and reinforced concrete silos (and other containers) tend to create overhangs. We solve such problems by systems of our air blasters. Air blaster shots remove material sticking to walls which provides constant flow and increases container’s working capacity. Air blasters are useful also on cement plant preheated towers, electrofilter charging hopper, to blast plugs or lumps in flow tubes etc.

Principle of operation

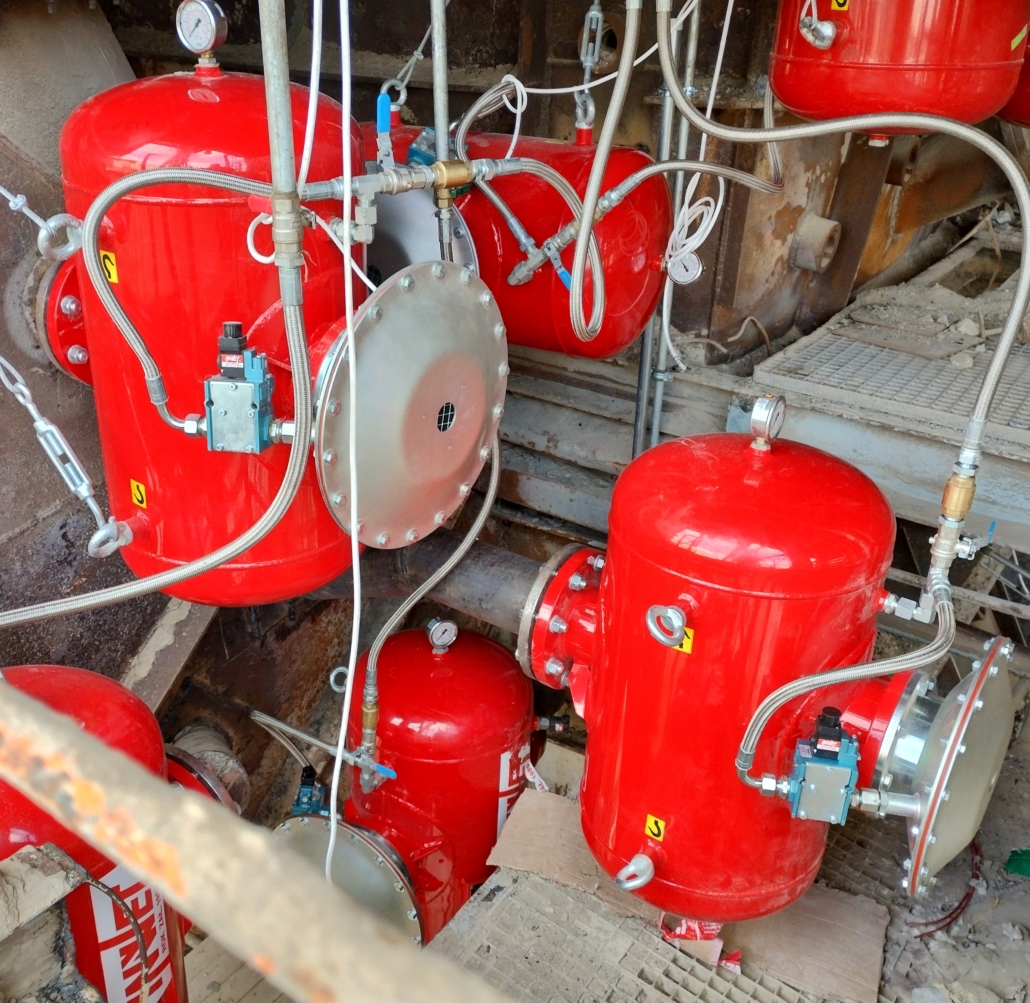

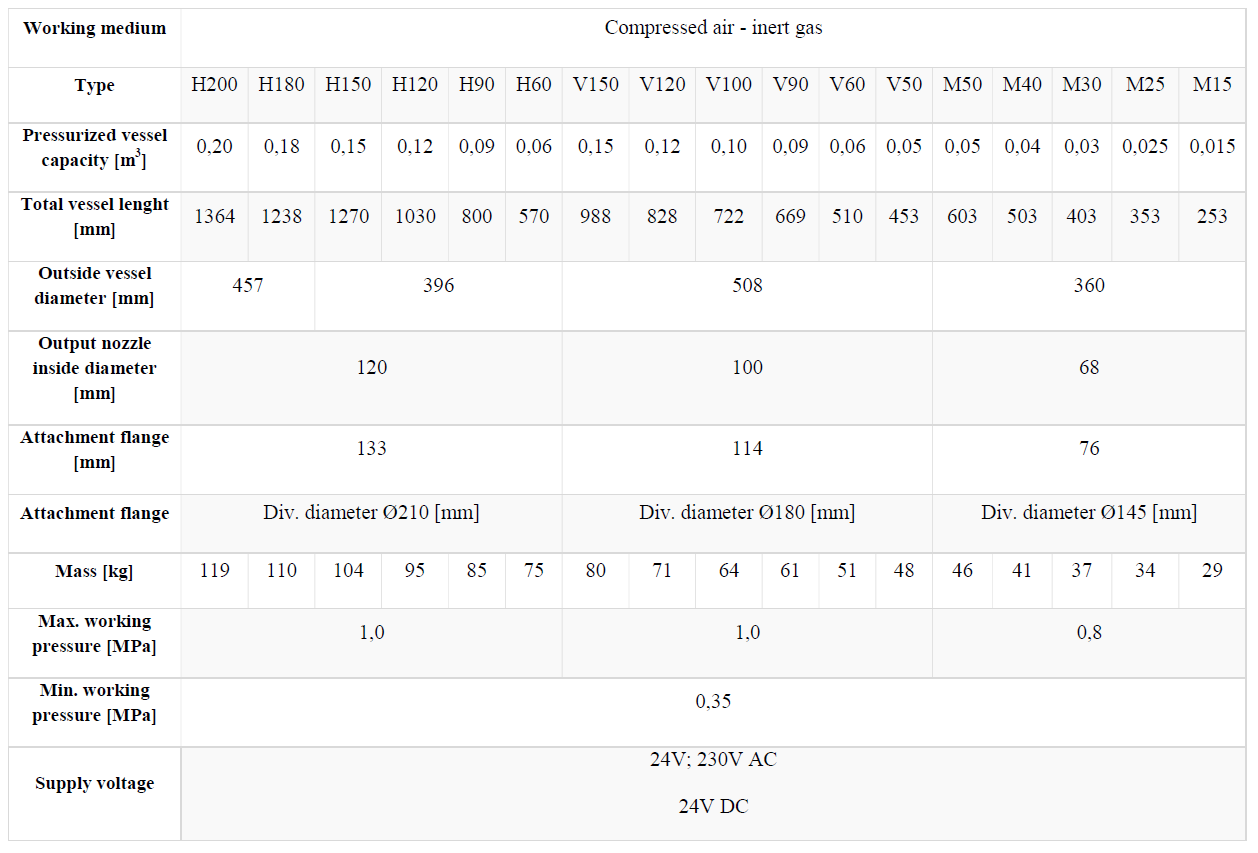

“SYNEX” air blaster accumulate and then releases in a rapid manner compressed air through directional nozzle. During filling pressurized vessel with compressed air, the air compressed (0,35 MPa – 1,0 MPa) flows from supply piping by non-return valve. Simultaneously compressed air is supplied to 3/2-way electromagnetic valve, installed on membrane head. Accordingly to the type of vessel, on one of 1/2″ pipes the pressure switch is installed. The switch shows action readiness. Control system then opens electromagnetic valve, starting the membrane head. Compressed air is released from the vessel in an explosive way. The output is automatically locked by spring action.

APPLICATION

The main purpose of air blasters SYNEX system is removal of overhangs and sludge banks, suspended materials, cakes etc. All these problems are related to storage and transportation of bulk materials in technological lines. Directed stream of compressed air, erupting from air blaster’s high pressure vessel, solves all mentioned complications. This dynamic stream – the blast – is precisely directed by a pipe and nozzle to the material adhesion zone.