VIBRATING SCREENS

Vibrating screens are used for sifting or fractioning bulk raw materials. Powered by realiable inertial drives, individually selected for every device.

We can distinguish one-deck and multi-deck screens, covered or open. Our offer contains full variety.

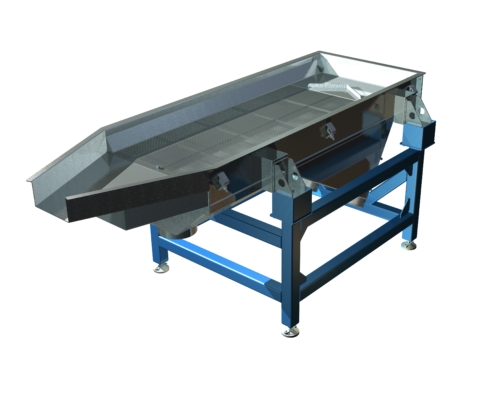

Linear vibrating screens

One-deck – produces two fractions. Also used to eliminate too big chunks before packaging or quality/control device.

Multi-deck – produces any number of desired fractions.

Table below shows basic technical data.

| Maximum dimensions (length x width) | 5m x 2m |

| Construction material | Stainless steel AISI 304 Stainless steel AISI 316 Coated carbon steel |

| Drive | Inertial drive |

| Support | Bar support construction with springs or steel/rubber hangers |

| Screen | Perforated steel sheet or mesh |

Vibrating screen

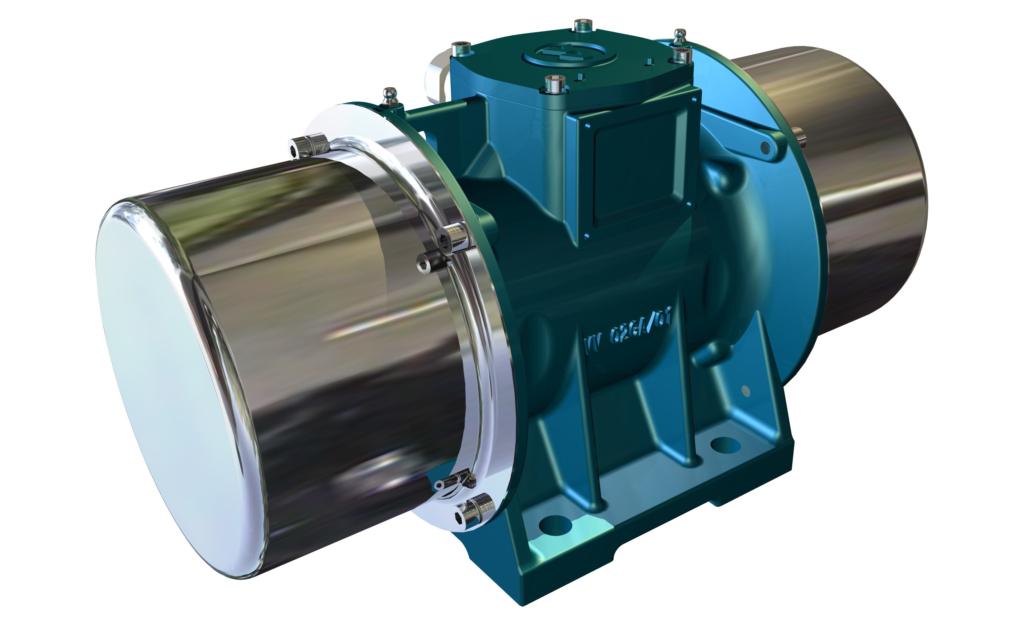

Interia drive

Hopper tank

Outlet of the superfraction

Outlet of the subfraction

Rotating vibrating screen

Rotating vibrating screen – selects solids from liquids or divides bulk material fractions (grain size from 0,033 mm to 51 mm). One device may contain from 1 to 4 screens. Standard models are equipped with screens from 440 mm to 1800 mm diameter. Easy to assemble and disassemble. Self-cleaning system are available. All product contact areas can be polished to be in accordance with Sanitary Standards.

Tumbler vibrating screen – is used mainly for fractioning or dust removal from dry, powdered or granulated products. Screens are moving in three directions similar to hand sifting. Perfect for light, delicate and crunchy substances. Maximum number of screens – 5. Standard models are equipped with screens from 1200 mm to 2600 mm diameter.

Control vibrating screen – is used mainly for control sifting. Removes unwanted bigger objects from product. The device is designated for granulates, powders and liquids. Grain size from 0,5 mm to 51 mm. Powered by two inertial drives installed horizontally which makes the device compact. Standard models are equipped with screens from 440 mm to 2200 mm diameter.

On request: ATEX certification, FDA IQ-OQ procedure, GMP can be provided.

Ball cleaning system for a sieve

Disc cleaning system for a sieve

Scrapers on top of the sieve

Ultrasonic cleaning system for a sieve